1. Introduction: More Than Just a "Click"

Have you ever wondered where that satisfying "click" or smooth tactile feel comes from when you're typing or gaming? It's not magic, but a marvel of precise engineering hidden beneath each keycap. This is the soul of a mechanical keyboard: the switch. A miniature mechanical device composed of a plastic housing, a precise metal spring, and clever metal contacts, it's more than just a simple switch; it's the key that defines your entire input experience. We'll delve into how these small wonders transform from raw plastic pellets and metal sheets, through complex industrial processes, to become the finely tuned instruments beneath your fingertips.

2. A Trip Down Memory Lane: From Typewriters to Esports – The Evolution of Switches

The story of mechanical keyboard switches dates back to the typewriter era. Early keyboards were cumbersome mechanical structures, where each keypress involved the movement of physical levers. The most iconic example was the legendary IBM Model M keyboard with its unique "Buckling Spring" technology. These keyboards were renowned for their unparalleled durability and distinctive, loud feel – veritable "tanks" on the office desk, virtually indestructible.

However, it was the German company Cherry that truly set the industry standard for modern mechanical switches. In the 1980s, Cherry introduced its revolutionary MX series switches. With their innovative cross-shaped stem design and modular concept, MX switches not only offered an excellent typing feel but, more importantly, opened the door to keycap universality. Like the "Coca-Cola" of the keyboard world, they quickly became the de facto industry standard.

Entering the 1990s, the rapid development of computer technology brought cost pressures. Cheap membrane keyboards, due to their low manufacturing costs, almost entirely dominated the market, and mechanical keyboards entered a "dark age," seemingly abandoned by time. However, in the early 21st century, with the rise of esports and a renewed appreciation for the typing experience, gamers and typists alike began to rediscover the superior performance and unique charm of mechanical keyboards, resurrecting them from their "graves" and ushering in a magnificent revival.

3. Inside Today's Factory: The Birth of a Switch

To understand why a switch delivers such a delightful experience, we must delve into its "innards," exploring its "ingredients list" and "cooking process."

Deconstructing the Switch ("Ingredients List")

A typical mechanical switch, regardless of brand or type, consists of several core components:

- Housing: Comprising the top and bottom parts, typically injection-molded from different types of plastic. The material of these plastics crucially affects the switch's sound profile. For example, Nylon usually produces a deeper, more rounded "thocky" sound due to its flexibility and sound-absorbing properties, while Polycarbonate (PC), with its higher rigidity, tends to deliver a crisper, brighter "clacky" sound. ABS and PBT are also common materials, each contributing unique acoustic and tactile characteristics.

- Stem: This is the only moving part of the switch, directly connecting to the keycap. The stem's shape, material, and surface smoothness are critical to the feel. Currently, POM (Polyoxymethylene) material is highly popular due to its self-lubricating properties, which significantly reduce friction, making the keypress feel incredibly smooth. The stem's color often differentiates the switch type (e.g., red for linear, brown for tactile).

- Spring: As the core power source of the switch, it determines the force required to actuate the key (actuation force) and the rebound force. Most springs are made of stainless steel, but their weight, length, shape (single-stage, dual-stage, or even triple-stage), and winding method can profoundly alter the switch's force curve and feel. For instance, heavier springs require more force to actuate, while longer springs might offer a more uniform keypress experience.

- Metal Contacts (Leaf): Tiny metal strips hidden inside the switch. When the stem is pressed down, it causes two metal contacts to meet, completing an electrical circuit and triggering the key signal. This component is crucial for the switch's electrical performance.

Journey Through the Production Line ("Cooking Process")

The manufacturing process of a switch is highly automated and precise:

- Injection Molding: This is the first step in creating the plastic housing and stem. Molten plastic is injected into extremely precise steel molds, cooling to form tiny, complex parts. Imagine making miniature LEGO bricks, but with even higher precision requirements, where a tiny deviation in the mold can affect the final product's quality. A high-quality mold can cost hundreds of thousands, even over a million dollars, serving as the foundation for product consistency and feel.

- Metal Stamping: Massive high-speed presses stamp out miniature metal springs and contacts from thin sheets of metal at a rate of several per second. The dimensions and shapes of these components must be precise to the micrometer level to ensure stable electrical performance and accurate spring force.

- Automated Assembly: Once all parts are ready, an army of robots takes over. In dust-free environments, highly precise robotic arms and grippers assemble the top housing, stem, spring, bottom housing, and metal contacts at astonishing speeds, often assembling several switches per second. This process demands extreme precision and automation to ensure correct alignment of all internal components within each switch.

- Quality Control: After assembly, every switch undergoes rigorous quality inspection. This includes electrical performance tests (ensuring contacts function correctly), keypress feel tests (checking for stickiness, abnormal sounds, or inconsistency), and even noise detection on some high-end production lines, to ensure every click is perfect and meets the preset standards. According to industry reports, leading manufacturers typically achieve a pass rate of over 99.8% for their switches.

4. Switch Terminology and Current Landscape

In the vast world of mechanical keyboards, there are established rules and classifications that form the basis of communication among enthusiasts.

Default Rules (Industry Standards)

- Cherry MX Dominance: Despite the emergence of countless switch brands, Cherry MX's cross-shaped stem design (commonly known as "MX compatibility") remains the de facto industry standard. This means you can almost freely swap any MX-compatible keycap, and this interoperability greatly enriches players' personalization options.

- 3-pin vs. 5-pin: Mechanical switches primarily come in two mounting styles: 3-pin and 5-pin. This merely refers to different ways of fixing the switch, similar to two-prong and three-prong electrical plugs. 5-pin switches (with two additional plastic locating pins) generally provide more stable mounting and can be installed directly onto the PCB, while 3-pin switches typically require a plate for added stability.

Choosing Your "Flavor" (Mainstream Switch Types)

Based on keypress feel and sound feedback, mainstream switches can be categorized into three main types:

- Linear Switches: Such as the classic Red and Black switches. These switches offer a very smooth feel throughout the entire keypress, with no distinct tactile bump or "click" sound. They press straight down to the bottom, providing uniform feedback. They are favored by many gamers (especially FPS players) due to their fast response and quiet operation.

- Tactile Switches: Such as the classic Brown and Clear switches. These feature a slight "bump" or "hump" mid-press, providing clear tactile feedback that the key has actuated, but usually without a loud sound. This "confirmation" makes them a versatile choice, offering a good balance for both typing and gaming.

- Clicky Switches: Such as the classic Blue and Green switches. These switches not only have a tactile bump but also produce a crisp, loud "click" sound. Each keypress is accompanied by both auditory and tactile satisfaction, making them a joy for many typists who appreciate clear feedback and the rhythm of typing.

5. The "Wars" and Woes of the Keyboard Community

The world of mechanical keyboards isn't always serene; it's also filled with controversies, challenges, and a unique community culture.

The Eternal Debate

The most classic "war" in the mechanical keyboard community revolves around the eternal debate of "which switch is best." Linear, tactile, and clicky switches – which reigns supreme? (Spoiler: There's no definitive answer, only endless forum debates and personal preferences.) Every new switch release sparks rounds of discussion, highlighting mechanical keyboard enthusiasts' ultimate pursuit of personalized experiences.

Community "Drama"

Keyboard communities occasionally experience "drama." For example, disputes over "clone switches" and design patents are common. When a switch design gains widespread popularity for its unique feel, the market often sees a proliferation of imitators. The classic "Holy Panda" switch incident is a case in point: this "modded switch," created by mixing parts from different switches, became a sensation due to its unique feel, leading to intense discussions, and even legal disputes, regarding its intellectual property and commercial production, underscoring the niche hobby's emphasis on innovation and originality.

Manufacturing Challenges

The difficulty of manufacturing high-quality switches is often underestimated. Developing a brand-new set of precision injection molds can cost more than a luxury car, and ensuring millions of switches achieve perfect consistency in feel, sound, and actuation is an immense challenge. Tiny tolerances and material batch variations can lead to subtle differences in feel, which are unacceptable to discerning users.

Environmental Concerns

- The Plastic Predicament: Keyboards, especially mechanical ones, are essentially plastic products. Although their lifespan is longer than membrane keyboards, the millions of switches produced annually still mean significant plastic consumption. Where do these plastics ultimately go after their product lifecycle? How to effectively recycle and process them is a severe challenge facing the industry.

- The Positive Side: Fortunately, mechanical keyboards alleviate the e-waste problem to some extent. Compared to disposable membrane keyboards, mechanical keyboards generally have a much longer lifespan, averaging 50 million keypresses, far exceeding the 5 million of membrane keyboards. Furthermore, their modular design allows switches, keycaps, and even PCBs to be repaired and replaced, extending product life and reducing overall e-waste generation.

- Future Trends: A growing number of manufacturers are recognizing the importance of environmental sustainability, actively exploring the use of recycled materials (such as recycled ABS or PC), developing single-material switches that are easier to recycle, and adopting more eco-friendly manufacturing processes. The aim is to meet user demand while minimizing environmental impact.

6. The Future is Now: The Next Frontier in Switch Technology

Innovation in mechanical keyboard switches never stops, with new technologies and trends reshaping our input experience.

Cutting-Edge Tech Emerges

- Magnetic Switches / Hall Effect Switches: These switches use magnetic sensing rather than traditional metal contacts for actuation. With no physical contact, magnetic switches offer extremely fast response times, theoretically achieving zero latency, and support adjustable actuation travel. This means gamers can customize key sensitivity to their needs, making them a new favorite for esports players seeking ultimate speed and precision.

- Optical Switches: Similar to magnetic switches, optical switches also avoid physical wear of metal contacts. They trigger signals by interrupting a light beam, offering extremely fast response times and longer lifespans. Currently, mainstream optical switch products generally achieve over 100 million keypresses.

Personalization Reigns Supreme

- Hot-swappable: This feature allows users to freely swap switches without soldering, much like changing LEGO bricks. It greatly lowers the barrier to DIY mechanical keyboards, letting players easily experiment with different switch types to find the combination that best suits their feel. Statistics show that over 70% of new mechanical keyboard products on the market now support hot-swapping.

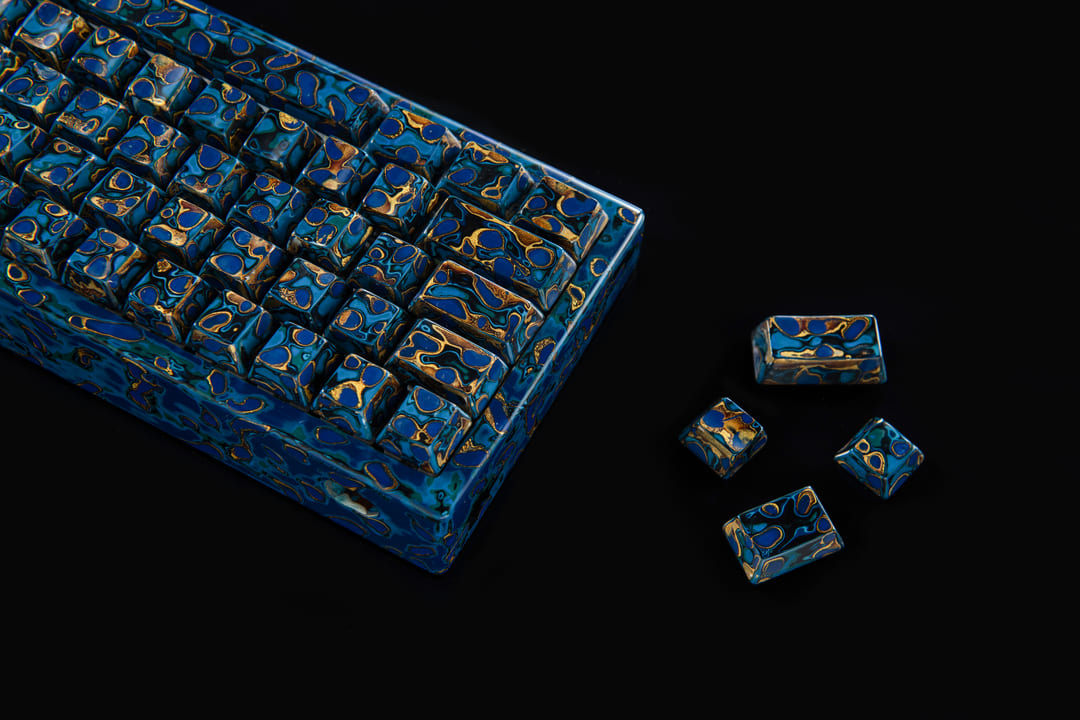

- The Art of Sound: The mechanical keyboard community's pursuit of sound has reached an obsessive level. From seeking "thocky" (deep, muffled thrumming) to "clacky" (crisp and bright), and even "marbly" (like marble colliding), players use various methods—changing housing materials, stems, springs, lubrication, and even adding sound-dampening foam inside the keyboard—to tune their unique and ideal "keyboard sound."

- Factory-lubed: Many high-end switches now come meticulously pre-lubricated from the factory, saving users the tedious step of lubricating them themselves. This means that out-of-the-box switches offer an incredibly smooth feel and a more pleasing sound, greatly enhancing the user experience.

Smarter Keyboards

- Artificial Intelligence (AI) Integration: Imagine a keyboard that intelligently adjusts switch actuation force based on your typing habits and work content, or even predicts your next input. While still in early stages, AI's potential in keyboard personalization and health reminders (like posture correction) is undeniable.

- Haptic Feedback: Haptic feedback technology can provide richer, more immersive vibrational feedback for each keypress, rather than just a single tactile bump. This can offer a more intuitive interactive experience in gaming and professional applications.

7. Conclusion: The Microcosm Under Your Fingertips

A tiny keyboard switch embodies decades of technological evolution, precise manufacturing, and a vibrant community culture. It's not just a simple input device; it's a bridge connecting humans to the digital world, a microcosm capable of conveying emotion through sound and touch.

Next time you type, take a moment to appreciate these engineering marvels beneath your fingertips. Each keypress is a tribute to technology, design, and craftsmanship. So, which "click" or smooth tactile feel do you prefer? Your answer defines your unique mechanical keyboard experience.

Frequently Asked Questions (FAQ)

Q1: Mechanical keyboards are much more expensive than membrane keyboards. Are they worth it? A1: For users seeking a superior typing experience, gaming performance, and durability, mechanical keyboards are absolutely worth it. They offer a much longer lifespan (typically 50 million keypresses or more), are highly repairable, and allow for customization of switches and keycaps to personal preference, providing an unparalleled personalized experience. In the long run, their durability and customizability often offset their higher initial cost.

Q2: How do I choose the right switch type for me? A2: This primarily depends on your personal preferences and usage scenarios: * Gamers: Often prefer linear switches (like Red switches) for their fast response and lack of tactile obstruction. * Typists: If you like clear tactile feedback but don't want too much noise, tactile switches (like Brown switches) are a good choice; if you enjoy a crisp "click" sound and strong feedback, clicky switches (like Blue switches) will be delightful. * Office environment: If people are around, linear and tactile switches are generally preferred over clicky switches to avoid noise disturbance. The best way is to try different switches in person to find the feel that suits you best.

Q3: What is "lubing switches"? Do I need to lubricate my mechanical keyboard switches? A3: "Lubing switches" refers to applying lubricant to the friction points of the switch (e.g., between the stem and housing) to reduce friction, eliminate unwanted sounds, improve smoothness, and enhance sound profile. For users seeking the ultimate feel and sound, lubing can make a significant difference. If your switches are "factory-lubed," additional lubrication is usually unnecessary. If they are not, and you're not satisfied with the current feel or want further optimization, you can try lubing them yourself or purchasing pre-lubed switches.

Q4: What is the benefit of the hot-swappable feature? A4: The hot-swappable feature allows users to insert and remove switches directly from the keyboard's PCB without soldering. This makes changing switches incredibly easy and is ideal for: * Experimenting with different switches: Trying various switch types without buying multiple keyboards. * Repair: Easily replacing a damaged switch. * Personalized customization: Installing different switch types for specific keys (like WASD or Enter). * Cost savings: Buying a barebones kit and installing your preferred switches.

Q5: What is the environmental outlook for mechanical keyboards? A5: Although mechanical keyboards use a fair amount of plastic, their modularity and long lifespan make them more environmentally friendly than membrane keyboards. Future trends include: * Using recycled materials: More manufacturers are adopting recycled plastics for switches and housings. * Easier-to-recycle designs: Developing single-material or easily separable components for better recycling. * Extending product lifespan: Emphasizing repairability and encouraging users to replace components rather than the entire unit. These measures are expected to effectively reduce the environmental impact of mechanical keyboards while meeting user demand.

แสดงความคิดเห็น

เว็บไซต์นี้ได้รับการคุ้มครองโดย hCaptcha และมีการนำนโยบายความเป็นส่วนตัวของ hCaptcha และข้อกำหนดในการใช้บริการมาใช้